The development of the quartz wristwatch was a turning point for the timekeeping industry and shifted the balance from Switzerland to Japan and the United States, despite the fact that the Swiss industry developed the first such watch. This is the story of the tumultuous and controversial creation of the world’s first quartz watch by the CEH in Neuchâtel.

Establishment of the Centre Electronique Horloger (CEH)

The Centre Electronique Horloger (CEH) was established in 1962 in Neuchâtel as a response to the emergence of alternative electric watch technologies. This was quite remarkable for two reasons: Swiss companies dominated the watch industry at that time and they already had a capable research laboratory, Laboratoire Suisse de Recherches Horlogères (LSRH) in Neuchâtel. But Gérard Bauer, head of the powerful Swiss Fédération de l’Industrie Horlogère (FH), saw clouds on the horizon in the form of electric and electronic watches. The CEH would be a defensive measure, returning expertise and importantly patents to Switzerland. Bauer hoped that this would be enough for their industry to evolve and weather this storm.

Image: New York Times, 12/16/1953

Although mass production of watches began in the United States, these techniques had been adopted in Switzerland in the early 20th century. After the Great Depression, much of the Swiss industry consolidated in various federations and cooperatives focused on horizontal integration. Throughout World War II, Swiss companies continued producing movement components and complete watches as other leading countries (the United States, France, England, Germany, Japan, and Russia) focused on war material. When the war was over, the Swiss were able to take over much of the world market, forcing most other manufacturers out of business.

Switzerland is a small country with limited resources and restricted labor, and the industry was still quite dispersed among small firms. But the Americans, French, Germans, and British could not rebuild and develop quickly enough to challenge Swiss watches, from cheap Roskopf movements to high-end automatic and luxury models. The United States spent the first post-war decade enacting tariffs and quotas to restrict imports, but the watch industry did not return. By 1960, only low-cost Timex and powerful Bulova were still producing watches in volume.

But the Swiss were so focused on mechanical watches they were slow to adopt technologies. Development of the electric (battery-powered mechanical) watch was driven by Franco-American cooperation between LIP and Elgin. Despite spending over a decade trying to perfect the technology, the pair only delivered a production model in 1958. Hamilton, also in America, was able to deliver a working electric watch a year earlier, but these were so unreliable it almost sunk the company. Still, the prospect of a battery-powered watch haunted the Swiss throughout the 1950s, a fact evident from reading the coverage in industry and popular press.

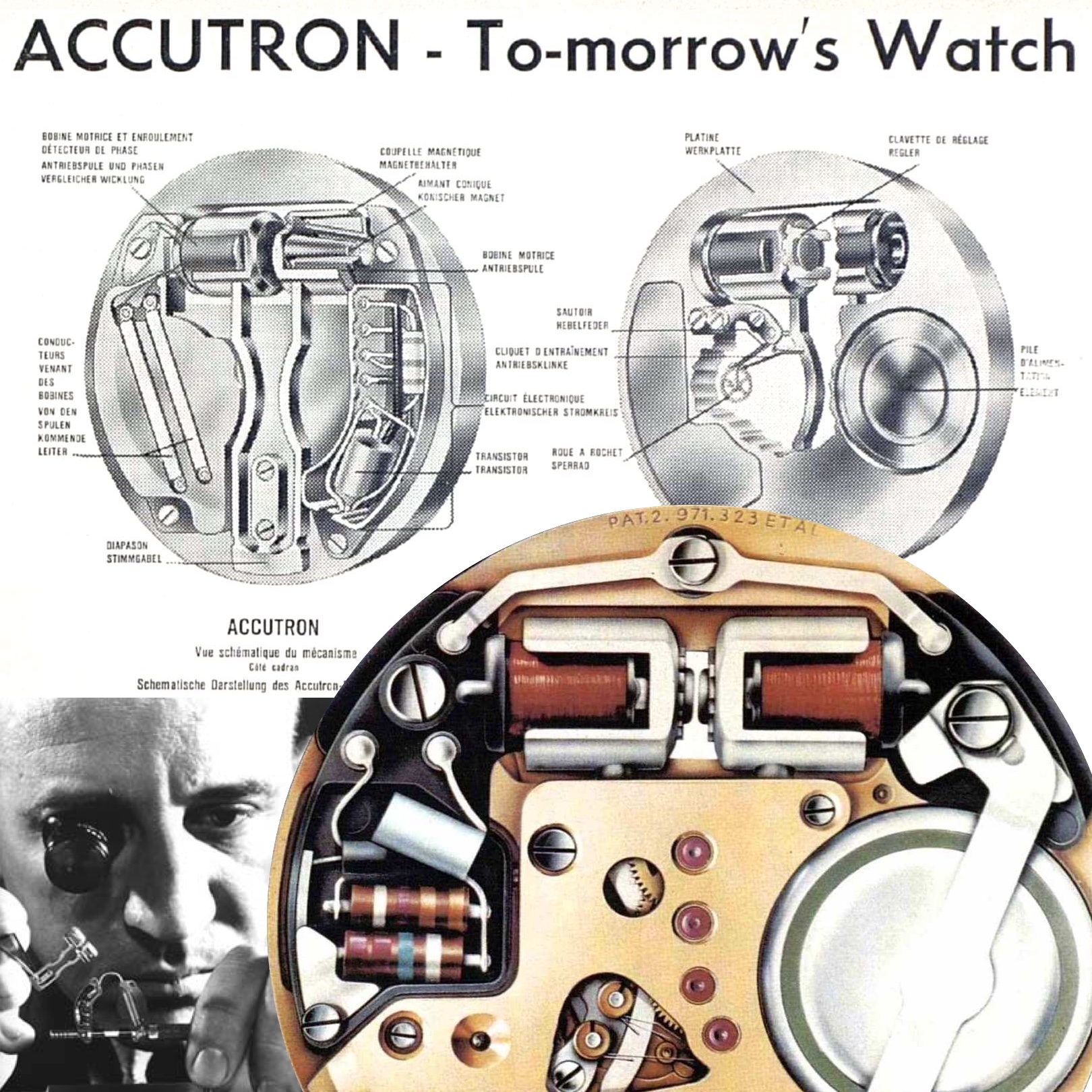

Ultimately, it would be a Swiss engineer that powered the Americans past the Swiss in watchmaking. Max Hetzel’s tuning fork movement, productized by Bulova as the Accutron, was the real deal. An electronic marvel, it was more accurate than any mechanical movement, rugged enough for daily use, and affordable enough to take on the entire mid-to-upper range of the watch market.

Image: New York Times, 10/26/1960

The entire industry was stunned when Bulova presented the Accutron tuning fork movement on October 25, 1960. Developed first in Switzerland and then in New York, the Accutron was a massive success. The company sold over 100,000 examples in two years, reaching one million examples by 1968. Built in the United States, the Accutron single-handedly postponed the demise of American watch manufacturing for over a decade.

Surprisingly, the prospect of the battery electric, electronic, and tuning fork watches apparently had no affect the product plans of most Swiss companies. Profits and exports were increasing every year, and the initial battery-powered watches were unimpressive. But FH President Gérard Bauer was among those who saw that these developments threatened Swiss dominance. Especially after the launch of the Accutron, it was obvious that the Swiss industry needed battery-powered watch technology of its own. Because the LSRH was focused solely on improving mechanical watches, a new organization was needed.

Officially inaugurated on January 30, 1962, the CEH was initiated by the leadership of Bauer at the FH with the support of Sydney de Coulon of the powerful movement-making consortium, Ebauches SA. Swiss-born engineer Roger Wellinger was chosen to lead the new institute in September, 1960, reportedly at the suggestion of industry champion, René LeCoultre. Wellinger had spent 15 years in the United States, first as an Assistant Professor of Electrical Engineering at the University of Illinois in Urbana and later at General Electric in Schenectady. His first task was to entice Swiss microelectronic talent to join him, with the search focused on those at American technology companies. By the end of 1963, seven engineers had been recruited from the United States and five more from the Ecole Polytechnique Fédérale (EPFL) in Lausanne.

Initial CEH Projects: Alpha and Beta

The CEH was founded with rather modest goals: To develop technologies better in at least one aspect than existing timekeeping technology, giving the industry an advantage in negotiations and licensing. The first employee, Eric Vittoz, quickly developed a prototype quartz clock, but the team determined that this technology would be impractical for use in a wrist watch: Any quartz crystal that was small enough to fit in a watch would oscillate so fast that the electronics of the day couldn’t keep up.

Despite Vittoz pioneering work on signal sampling and projects at various Swiss universities, the quartz project was abandoned. Rather than develop a quartz movement, the team focused on other areas of electronic timekeeping. There was much focus on semiconductor integrated circuit (IC) technology and sonic resonators akin to the Accutron.

Kurt Hübner, hired out of pioneering American company Shockley Semiconductor, was put in charge of semiconductor development. The team focused initially on bipolar transistors, as pioneered by William Shockley, and high-impedance resistors. There progress allowed the team to develop a full integrated circuit, including a production line at Neuchâtel. This attracted the attention of the Communauté Industrielle Suisse SA (CISSA), which included various Swiss companies as well as Philips of the Netherlands. They would spend most of 1964 trying unsuccessfully to buy out the CEH for this IC technology.

It was critical that the CEH be neutral and that none of the Swiss companies funding the effort took unfair advantage. Therefore most of the work of the CEH was a closely-guarded secret, even within the organization. By 1964, two different wristwatch projects were under way, using the code names Alpha and Beta. Although common terms for stages of software development today, these were simply code names and not a comparison of the relationship between these projects.

- The Alpha project, under the leadership of Heinz Waldburger, was working on a sonic regulator in the shape of a figure 8. This would be resistant to positional/gravitational influence, unlike the Accutron tuning fork, and might escape some of the Bulova patents.

- The Beta project, lead by Max Forrer formerly of Stanford and GE, paired a conventional tuning fork with a frequency divider. This triggered a piezoelectric or electro-magnetic vibration motor, which drove the wheel train, and would thus not be covered by other Bulova patents.

Although none of this work was part of an effort to develop a quartz wristwatch, much of it would be pivotal to the eventual Beta 21 movement. Hübner’s ICs would power the quartz resonator and divide the frequency, leveraging Vittoz’ work, and Henri Oguey’s vibration motor would turn the wheel train. But all of this was kept secret, even from the sponsoring companies, for fear that one would take the technology for themselves. Instead, each researcher was tasked to investigate one area or another in seclusion.

1965: The Birth of Quartz

Image: Eric A. Vittoz

On May 7, 1965, while CEH management was in America, researchers Armin Frei and Rolf Lochinger were discussing the challenges of developing a new oscillating organ. Free had been assigned to look into piezoelectric ceramics and metallic crystals, but his thoughts inevitably turned to quartz. Free believed that he could create a miniature quartz rod crystal that would vibrate slower than 10 KHz, reducing the power draw of the system. An chain of binary “flip-flop” transistors could reduce this to a usable frequency, a novel driver circuit could power it, and the CEH could implement this in an integrated circuit. Frei and Lochinger spent the next six months developing a prototype quartz oscillator in secret.

The pair’s progress radically altered the strategy of the CEH. On November 26, 1965 Wellinger declared that the organization’s focus for 1966 would be to construct a “montre-bracelet à quartz,” or quartz wristwatch. Frei was successful in creating an 8,192 Hz quartz oscillator in 1966, along with a driver circuit and frequency adjuster. These were implemented in ICs by the semiconductor department and watchmakers were able to construct a working prototype by the end of the year. In 1967, a working watch was within sight. Meanwhile, Jean Hermann created an innovative temperature compensation circuit.

Image: CSEM

The complete movement was now known as Beta 1, though it was quite different from the original Beta project. A prototype with the Beta 1 movement, known as CEH 1020, was constructed by Jean Hermann and François Niklès in 1967 and submitted for testing at the International Chronometric Competition in Neuchâtel along with later prototypes. This was the world’s first quartz wristwatch movement.

The 14-stage frequency divider used in the Beta 1 reduced the frequency to 0.5 Hz, with an anchor-style stepper motor advancing the wheel train once per second. This was not as power-efficient as desired, so Max Forrer’s circuits department stepped in. They created an alternative movement, known as Beta 2, with a simple 5-stage frequency divider driving a vibration motor at 256 Hz. Although not as elegant, Forrer’s Beta 2 design was efficient enough to run for over a year on a single battery cell. Prototypes of Beta 2 were also submitted to the 1967 competition.

Image: Eric A. Vittoz

Seiko also entered a prototype quartz watch at the Neuchâtel competition that year, underlining the importance of the work at CEH. But the Swiss Beta movements took the top 10 spots at the competition, thanks in large part to Hermann’s thermo-compensation and Frei’s fine adjustment circuit. The pace of development is quite remarkable: The CEH quartz movement progressed from an idea to a world-beating prototype in just over two years. More shocking was the impact of these quartz chronometers: They performed so well that the Neuchâtel Observatory ended their chronometer competition permanently!

Image: Europa Star 104, 1968

Prototype to Production

After the February 15, 1968 release of the Neuchâtel competition results, it was clear that the CEH movement must be put into production as quickly as possible. The organization had succeeded in creating a world-beating technology, but the Japanese were close behind. Because Forrer’s Beta 2 was able to deliver battery life of more than a year with existing technology, it was decided that Frei’s design would be shelved. The final product would be named “Beta 21,” which should be thought of as “two-one” rather than “twenty-one” because it is the first product based on the Beta 2 prototype.

Armin Frei’s animosity toward Forrer’s team is evident in his writing, and he left the CEH in 1967, followed by Lochinger the following year. Roger Wellinger also left that year, with Frei claiming that he was fired and other sources noting simply that he resigned over internal differences. It is likely that the secrecy of the Beta project was the cause of Wellinger’s ouster: By not telling the shareholders of their progress until an August, 1967 meeting, he lost their confidence and was subjected to an investigation of his management by an external auditor. Even the December, 1967 seminar, demonstrating all they had accomplished, did not save his position.

Ironically, although he was opposed to quartz as impractical, Forrer became a champion of the technology and he was credited as its primary inventor until recently. Forrer took over as Director of the CEH in May, 1968 and focused the organization on productizing the movement. An amusing story has Forrer visiting Hewlett Packard in California that year and discovering that their prototype atomic clock was off by 2 seconds, according to his Beta 2 wristwatch.

ETA was hedging their bets, however. Max Hetzel, inventor of the Accutron, had resigned from Bulova in 1963 and returned to Switzerland. By 1966 he was working inside the CEH on an improved tuning fork movement, and in 1968 ETA licensed the Bulova patents. Soon after, the ETA/Derby Swissonic Mosaba line of tuning fork movements was introduced, based on Hetzel’s work at the CEH. Once it became clear that the CEH would focus on quartz in 1967, Omega bought Hetzel’s work and he continued work there on advanced tuning fork movements. It is likely that, in addition to allowing Ebauches SA to create their own tuning fork movements, this patent licensing deal enabled the CEH to use a vibration motor in the production Beta 21 movement without fear of a legal challenge from Bulova.

The CEH completely redesigned the Beta 2 movement to create the production model. A calendar complication was added, with an instant date change and quick-set by pressing and rotating the crown. The driver and divider were combined on a single integrated circuit with 110 electronic components in all. Although primitive by today’s standards, it was a feat of manual layout and resulted in a a chip just 2 mm on a side.

The Beta 21 movement would prove extremely difficult to produce, and on May 22, 1969 an agreement is reached to divide production between three firms. The integrated circuit was challenging to produce and test, and would be produced internally in Neuchâtel. Ebauches SA took on the delicate task of constructing the quartz crystals as well as other mechanical parts. Finally, the vibration motor was constructed by Omega, since it was similar to a tuning fork. These were assembled by Ebauches Electronique SA of Marin, Switzerland.

Image: The Eastern Jeweller & Watchmaker (Europa Star) 117, 1970

The race was on to produce the first quartz watch. Longines beat the rest of the industry and announced the first production quartz wristwatch on August 20, 1969. Lacking integrated circuit expertise, the Ultra-Quartz used a tangle of discrete electronic components and incorporated an odd “cybernetic” design that incorporated a feedback loop. It is not clear when these watches were delivered for sale, with some claiming 1971, but this would be the world’s first quartz watch announced for production.

Seiko was next, releasing their Quartz Astron for sale in Japan on December 25, 1969, though in limited numbers. Cal. 35SQ used a stepper motor like the Beta 1 and is usually credited as the world’s first production quartz watch. Seiko’s technology advanced rapidly, with a low-power CMOS divider IC delivered in 1970 in the follow-on Cal. 36SQC and true mass production in 1971 with Cal. 38SQ.

American companies were also hard at work, with Hamilton announcing the Pulsar LED watch in 1970 but not able to deliver it until 1971. Bulova, although a member of the CEH, was working to integrate a quartz crystal with their Accutron movement. A so-called Accuquartz desk clock was on the market in 1969, with a production hybrid watch movement following two years later.

Launching the Beta 21

Image: The Eastern Jeweller & Watchmaker (Europa Star) 117, 1970

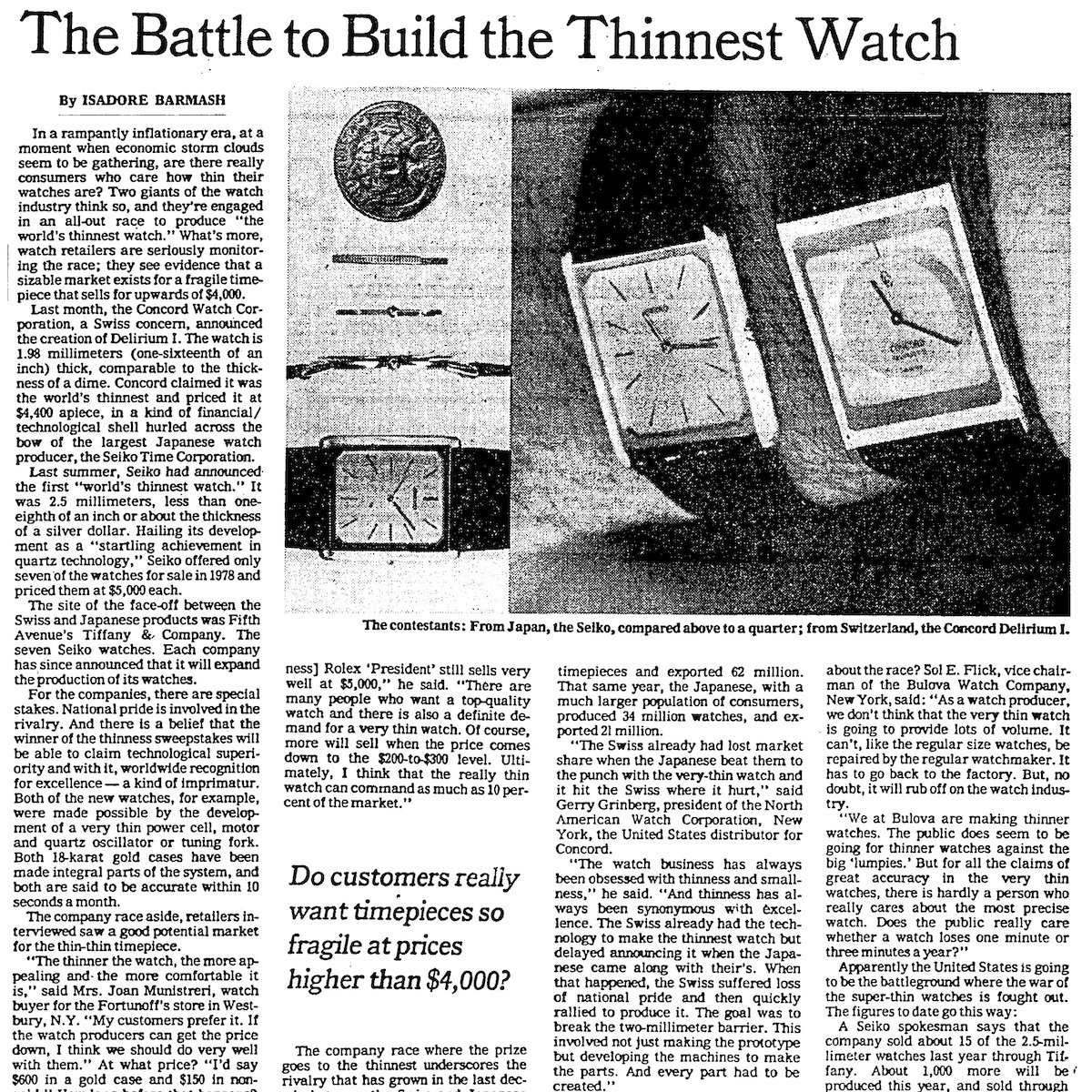

The Swiss industry knew that they had to respond in force. On April 10, 1970, the Basel Fair opened with more than 20 Swiss quartz watches on display. Most used the CEH Beta 21 movement, of which 6,000 examples would be produced in total. Bulova (“Accuquartz”), Enicar (“Quartz-O-D”), IWC, Longines (“Quartz-Chron”), Patek Philippe (“Cercle d’Or”), Piaget, Rado (“Quartz 8192”), and Rolex (Cal. 5100) all showed Beta 21 watches at the Fair that year, though most would be modified significantly before release. Omega would produce a Beta 21 model (“Electroquartz”), though they do not appear to have shown it at the Fair.

Because it was a large movement and 6.2 mm thick, the initial Swiss quartz watches were quite unusual in design. Most featured thick rectangular cases, with quite a few being angled so the dial faced the wearer. Thanks to the rectangular shape of the movement, it was difficult to package a Beta 21 movement in a round case. IWC’s round Basel Fair design would be dropped in favor of a rectangular (“International”) or hexagonal (“Da Vinci”) case soon after. Patek Philippe’s model featured a unique case with a TV screen shaped dial, while the Rolex Quartz had a more traditional look apart from the lugs.

Image: The Eastern Jeweller & Watchmaker (Europa Star) 117, 1970

Another issue with the Beta 21 movement was its cost. Because it was hand-built by the top companies in the industry, most examples were cased in gold and sold for as much as 20,000 Swiss Francs. This made them some of the most expensive watches available at the time. Still, the CEH was able to deliver the first 1,000 watches in the first half of 1970, far more than the earlier Seiko or Longines models.

Not every member of the CEH would ultimately produce and sell a Beta 21 watch. Doxa, Elgin (“Lord Elgin”), Jaeger-LeCoultre, Universal (“Uniquartz”), Zenith, and Zodiac showed watches that were not produced. Credos (Bucherer) and the Communauté d’Horlogerie de Précision (Borel/Cyma/Doxa, Ebel/Juvenia/Eberhard, Favre-Leuba, and Zodiac) “Modul-O-Quartz” may have been produced in small volumes, but these are not well-documented.

Other Swiss companies also displayed their own quartz watches at the 1970 Basel Fair. Girard-Perregaux partnered with Thomson and Motorola to develop the Elcron movement, which solved the power drain issue by using two batteries. Omega showed the 2.4 MHz Megaquartz, though they were also in the Beta 21 club. Longines showed their in-house Ultra-Quartz alongside their Beta 21 Quartz-Chron. And newly-formed Neosonic was at the fair to pre-announce their 16 KHz quartz technology, despite it not being production-ready. A joint development of Certina, Hamilton/Büren, Roamer, and Rolex Bienne, Neosonic’s design was quite similar to Anton Frei’s Beta 1 but was never produced.

Image: The Eastern Jeweller & Watchmaker (Europa Star) 120, 1970

Another interesting aside is that the 1970 City of Geneva Prize focused on novel designs for a Beta 21 watch. The competition provided the specifications (but apparently not the movement) to a number of watch designers. The winner was Hans Boeckh of H. Stern do Brasil, who penned a “mystery dial” watch in an unusual trapezoidal case. All of the entries reflected the emerging funky styling trends of the 1970s, and featured bold, chunky elements to hide the bulk of the movement. The fact that the Beta 21 was the centerpiece of this prestigious design competition shows how important it was that year. This was the first time that the prize called for a specific design for a watch based on an existing movement.

CEH and the Beta 21: Aftermath

In all, 6,000 Beta 21 movements were produced through 1972, plus perhaps 600 more for testing and development purposes. The design was modified with a thinner battery and revised trimmer and quartz module that year. As many as 50,000 examples of the second-generation version were produced. Although this movement is often called “Beta 22”, I could find no contemporary reference to that name. Omega handled the construction of many of these later movements, branding them Cal. 1301 and 1302, and this is the most common name regardless of brand.

By this time, the Beta 2 design was showing its age. Most companies had settled on a dead beat stepper motor design, as pioneered by the Beta 1 and Seiko Astron and famously adopted by Girard-Perregaux with their 32 KHz Cal. GP350. Girard-Perregaux and Seiko also lead the way in leveraging American semiconductor expertise, partnering with Motorola and Intersil, respectively, for advanced integrated circuits. This dramatically reduced power consumption and allowed the use of faster crystals. Where the Beta 21 operated at 8 Hz, most quartz watches since the mid-1970s have used a 32 KHz crystal.

Image: The Eastern Jeweller & Watchmaker (Europa Star) 127, 1972

The CEH did in fact produce “Beta 3” and “Beta 4” movements in later years. Beta 3 was the first version to use a CMOS integrated circuit. Developed by Fritz Leuenberger and Eric Vittoz, this reduced power consumption of the frequency dividers by a factor of 20, opening the door to a higher-frequency crystal. Beta 3 also eliminated the quartz oscillator trimmer, simply “throwing away” pulses instead. This required on-board memory to tune it to the crystal, which was accomplished at first with a number of small switches. Although an important development, Beta 3 was not directly put into production.

Beta 4 was a major advancement, using a 524 KHz quartz resonator and more-advanced digital tuning system based on the Beta 3. Put into production by Piaget (Complication SA), it used volatile RAM to store the tuning information. This was adjusted using a special external timing station, which sent digital pulses to the RAM using magnetic coupling, similar to how Qi wireless charging works today. Introduced in 1975, Piaget chose not to highlight this advanced technology and simply relied on their reputation as the producer of the best watches at the time.

Although rapidly eclipsed technically and set aside in favor of other models, the Beta 21 has proved quite collectible. Reliability is somewhat better than other early electronic movements, but service components mar some examples. Ebauches SA developed replacement quartz modules with small 32 KHz crystals and these are often found in running examples today. And some vendors simply swapped out the entire Beta 21 movement for a later ETA/ESA quartz movement, destroying collectibility entirely.

After producing the Beta 21, the CEH returned to its role researching electronic watch components under the leadership of Max Forrer. Eric Vittoz’ paper details many of the later developments, including work on CMOS chips, improved frequency dividers, and low-power electronics. CEH was combined with the Fondation Suisse pour la Recherche en Microtechnique (FSRM), and the Laboratoire Suisse de Recherches Horlogères (LSRH) in 1984, becoming today’s CSEM.

The Grail Watch Perspective: Beta 21 was the Product of Many

The development of the quartz watch at the CEH was carried out in secret, with multiple teams working on various aspects of the final Beta 21 movement. There are obvious differences in recollection and assignment of credit among the various groups involved, along with disagreement over personal accomplishments and accusations of plagiarism. This is especially apparent between Armin Frei and Max Forrer, but there seem to have been many factions and personalities involved. The visionary Roger Wellinger left the CEH in 1968 over “internal differences”, Forrer took much of the credit for the Beta 21 project, and Piguet gives scant credit to Frei and does not even mention Lochinger. Eric Vittoz’ account seems the most even-handed, but he was focused on the problem of frequency division and circuit design.

My college degree focused on the interaction of science and technology, and this gives me some perspective on this controversy. No advancement in science or technology is the product of any one individual, and no flash of insight is so brilliant that it can come into existence without perseverance. It is impossible to say who is right, but we can try to get to the heart of it by studying a variety of sources and considering the most likely narrative.

Every modern source agrees that it was Dr. Armin Frei’s creation of a watch-sized low-frequency quartz crystal that made a quartz watch practical, and most agree that he was personally involved in most design elements of the Beta 1, the world’s first quartz wristwatch movement. And it was this breakthrough that inspired Roger Wellinger to declare the creation of a quartz wristwatch to be the focus of the CEH in 1966. But even Frei’s own account shows that Beta 1 would not have been possible without the support of Roger Wellinger, the integrated circuits of Kurt Hübner, the frequency divider of Jean Fellrath, the oscillator and divider implementation by Raymond Guye, the temperature compensator of Jean Hermann and Fritz Leuenberger, and the stepper motor of Hermann and Françoiis Niklès. At the same time, Max Forrer’s team quickly re-worked his original Beta movement to incorporate Frei’s quartz oscillator along with a divider created by Eric Vittoz.

Reading other accounts, it is clear that the concept of a quartz wristwatch was widely considered even before the creation of the CEH. Indeed, the first project of the first CEH employee, Eric Vittoz, was the creation of a quartz clock! But the daunting challenge of bringing this technology to the wrist (namely miniaturization of the crystal oscillator and power consumption of the divider circuit) convinced the CEH management and staff to focus instead on other aspects of electronic timing in the interest of shorter-term results for the Swiss industry. Frei himself spent his first years at the CEH investigating miniature low-frequency oscillators before deciding to have another go at a quartz oscillator in secret.

They say that genius is 1% inspiration and 99% perspiration, and Armin Frei combined both in the creation of the world’s first quartz wristwatch. But many others also contributed, and the production Beta 21 movement incorporated the work of many others, notably Eric Vittoz and Max Forrer, who became director of the CEH in 1968 after Wellinger resigned. By this time, Frei and Lochinger had also left, and the job of producing the movements fell to others. The 6,000 Beta 21 movements were the product of multiple companies and were based on the ideas of many individuals. Who created the world’s first quartz wristwatch? The CEH did.

References

- The Electronic Watch and Low-Power Circuits, Dr. Eric A. Vittoz, IEEE: An excellent recollection of the development of the CEH, the creation of the first quartz watch, and further work in CMOS and novel electronic circuits. Vittoz was the first engineer hired by Roger Wellinger at CEH and remained with the Center through the 1970s.

- History of the First Quartz Wristwatch, Dr. Armin H. Frei, The Dr. Armin H. Frei Heritage Estate: An important counter-narrative by the inventor of the miniature quartz oscillator that made the CEH quartz watch possible. The Estate is committed to making the impact of Dr. Frei’s work known to the world, as it was widely overlooked for decades.

- The First Quartz Electronic Watch, Christian Piguet, reprinted in Integrated Circuit Design. Power and Timing Modeling, Optimization and Simulation: Another account of the creation of the first quartz watch, with important perspective from a younger member of the CEH team.

- The Evolution of Time Measurement, Part 2: Quartz Clocks, Michael A. Lombardi: A general history of the use of quartz oscillators for time measurement.

- Crazywatches.pl, an enthusiast website focused on electric and electronic watches.

- WATCH. History of the modern wrist watch, by Pieter Doensen, which has an excellent timeline of the CEH Beta 21.

In 2020 I became the proud owner of a Rado Diastar. A watch that adorned the inside-cover of International Men’s magazines for the better part of 2 decades. Hitting the quartz-bandwagon was essential for Swiss watchmaking to survive the digital revolution, but they always did it “different” to the Japanese. The caliber 193, during inspection while doing a battery-change, strongly indicates the quartz technology and its accompanying circuitry, was done by hand. Completely over-engineered for it’s task, with gold solder (and everything else being gold on the ETA 988.333), it will clearly last well into the coming decades. Thick, heavy solder-lines show you can make a quartz watch and make it beautiful, at the same time. Absolute master-stroke to use gold (or a gold amalgam) solder puts this “digital watch” far into the space above generic micro-controller, mass-produced watches. It may be a dual Analog/digital watch, but it has the circuitry made to last decades, and then some!