Le Locle is the birth- and work-place of Daniel JeanRichard, initiator of the Swiss watchmaking industry way back in 1672. He established the system of établissage, wherein a watch would be constructed from components created by specialist suppliers. So it is appropriate that, on my recent visit to the heart of the Swiss watch industry, I stopped in Le Locle and constructed my own watch!

Constructing Watches in the Neuchâtel Region

Le Locle, and nearby La Chaux-de-Fonds, was the center of the second wave of Swiss watchmaking. Rather than building complete watches by hand like the masters in Geneva, JeanRichard and later watchmakers like Abraham-Louis Perrelet championed a division of labor. Workers would specialize in particular watch components (dials, hands, cases, and various movement parts) and these would be brought together into a complete watch. Later American-style mechanization and industrialization rose in the East in the Jura triangle before spreading through the whole region.

This history of watchmaking by assembly made my visit to Les Apprentis du Temps especially appropriate. Just like my forebears, I would choose various components and assemble them myself into a finished watch. And my work would take place in a school used during the week to train watchmakers from local companies like Tissot.

There are a few such opportunities in the area: In addition to Les Apprentis du Temps in Le Locle, there are the Centre Horloger and private workshops at the Beau-Rivage Hotel in Neuchâtel, Le Carrousel des Montres, Le Monde est Carré, and workshops by Cimier at Musée International d’Horlogerie in La Chaux-de-Fonds. I arranged my workshop through Tourisme Neuchâtelois – Montagnes in La Chaux-de-Fonds, and I imagine they could arrange most of these other workshops as well.

You would also probably enjoy this article about my trip to Switzerland: My Visit to the Swiss Jura, Home of Watchmaking

Planning My Watch

I emailed Tourisme Neuchâtelois just a few days before my visit to the region to inquire about these various workshops. Stéphanie Bavaresco responded quickly and worked with me to find an opportunity that fit my schedule at Les Apprentis du Temps. I was quite surprised she was able to arrange it at all: Les Apprentis du Temps advertises just two days per month for their workshops, and most businesses in the area are closed on Sundays. Nevertheless, a workshop in English was arranged for Sunday afternoon.

|

|

|

|

Once we agreed on the workshop and I paid the fee to participate (CHF 1,000, including the watch), it was time to design my watch. I was sent a list of components to choose from: Five different dials, four sets of hands, four straps, and four cases. There were two more options: A deployant clasp and a decorative box.

Since all of the dials featured Breguet numerals, I decided to create something of a classic-looking watch. I selected a silver face with guilloche and black pomme-style hands to give it a classic look. These would go in a silver case with an oversized onion crown. A black strap completed the look I was going for.

I found the other faces and cases somewhat odd: A PVD case seems too sporty for Breguet numerals, as do the contrasting stitching on the other straps. Yet all three photos in the selection document featured this combination. Clearly these are watch assemblers, not watch designers.

My Experience at Les Apprentis du Temps

My appointment was Sunday afternoon at 2 PM, and I made sure to arrive on time. Les Apprentis du Temps is located in an ordinary looking building on the outskirts of Le Locle, with simple signage and a very industrial feel. It is, after all, a working school for watchmakers. I was the only “apprentice” that day, suggesting that Ms. Russo, the school’s teacher, had arranged to come in just for me. She brought a student along to serve as my primary instructor since his English was better.

The movement, components, and tools were arranged for me on a watchmakers bench, and I immediately noticed a problem: The case was the unfortunate PVD option rather than the silver I thought I had selected! It turns out I checked the wrong box on the form, but Ms. Russo was able to locate the silver one I wanted.

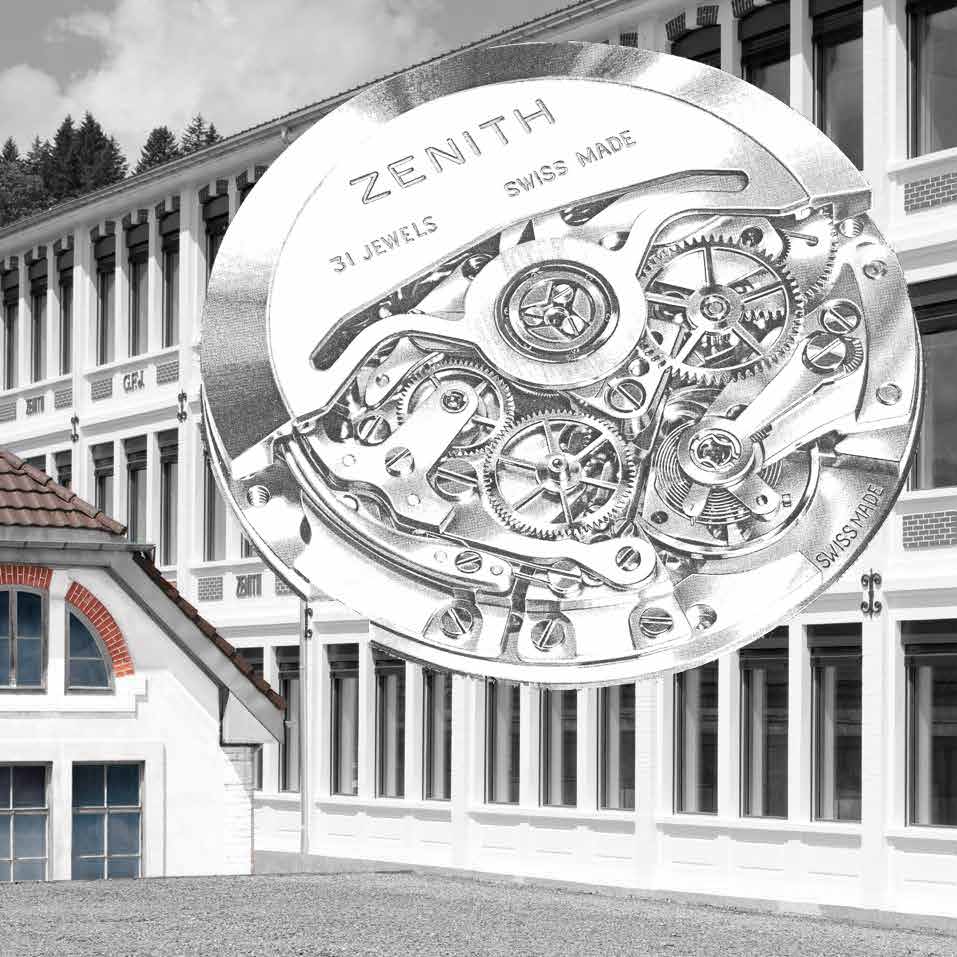

I began with a bit of basic instruction on how to sit and which tools we would use, including putting on the ubiquitous pink finger protectors used by watchmakers. I would have appreciated more direction and background, but we dove right in. We released the movement (an ETA 6498) from its plastic shipping case and I was shown how to clean it with some blue tacky material. But before I even started examining it, we were on to the next step.

I loosened the screws to attach the dial to the movement and carefully fitted it in place. Only after this did I notice that we had forgotten a washer between the main wheel and the dial, so off it came once again. I appreciated learning that these watchmakers work by “feel” rather than measurements – all pieces should fall nicely into place and fit together without much force.

Next was the hardest part: Fitting the hands. Although the 6498 is a large movement, the seconds hand is tiny and extremely difficult to work with. It took a great deal of time and effort to get it aligned perfectly, and just when I thought I had it in place the movement would spring to life and tick backwards, forcing us to start over. With much help, I finally got all three hands in place, aligned, and pressed to fit. Once again, we held the hand press tools in hand rather than in the jig they were made for.

I placed the completed movement/dial combination carefully in the case and used affixed it with screws. Then I screwed on the back and attached the band. I had done all these tasks before, so this gave me a chance to relax and chat a bit with my hosts. This is when I learned how long the students study (a year for movements, another year for polishing) and that the local companies send their watchmakers to this very room to learn how to work with new movements.

My Impressions

I was pleased overall with my experience at Les Apprentis du Temps. The finished watch is lovely and the experience was well worth the price. It was a remarkable way to come to understand Le Locle and the modern practice of watchmaking.

I would have appreciated more instruction before each step, however. While visiting the Musée International d’Horlogerie, I saw the Cimier class in progress and they received much more detail from the instructors, including background on each step via a projector screen. But their class, held in the museum, was much more touristy and less authentic than mine.

Since we had some extra time, I also would have liked to do more work on the watch. We could have disassembled the movement a bit and talked about the components. We could also have put the running movement on a machine to check its accuracy. And we could have worked on polishing the case a bit. It really felt a little anti-climactic and casual at the end. Again, this gave it authenticity but took away a bit from the fun.

Although not perfect, I truly enjoyed my experience at Les Apprentis du Temps and would recommend any reader of this blog to attend!

[…] to build your own watch? Stephen did. And he actually did! Check out his story. Definitely something cool to do if you have a spare day in the right part of […]